Making A Robot

Page 5

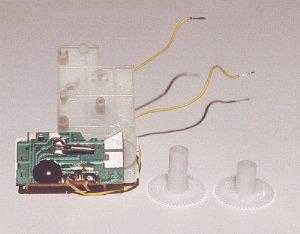

A Photovore driving two clock motors

Modifying a clock

The Photovore circuit on the previous page drives a modified clock mechanism. This is the standard mechanism you find in most “ticking” clocks. It contains a 1.5v cell and a crystal-driven chip that pulses a “magnetic rotor” once a second. This motor drives a train of gears to activate three hands.

Clock motors take very little current and can be easily driven from the output of gates. Here are the instructions for modifying one of these mechanisms:

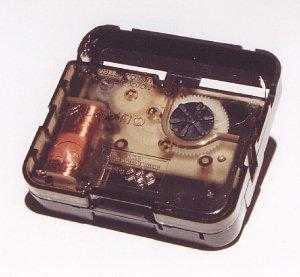

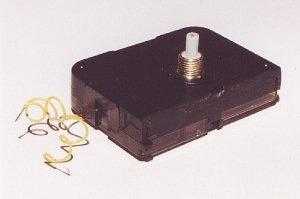

A clock before modification. Open the case with a screwdriver by spreading the snaplocks.

The components inside can be clearly seen.

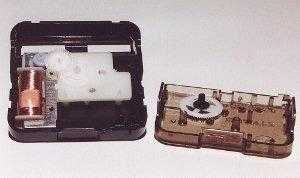

Don’t let all the parts fall out. You have to be able to re-assemble most of the gears.

Remove the first gear and the gear/shaft of the seconds hand.

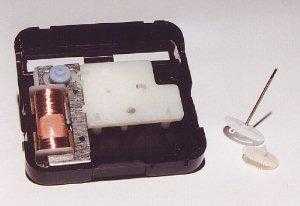

Take the stepping motor plus subframe and PCB out of the case; they form a single part. Cut the copper foil between the chip (black lump) and the right coil contact using a small dentist’s drill or a sharp knife. Solder two thin insulated wires (about 5 inches long) onto the coil. Be careful not to unsolder the coil wires. There is no need to use different colours: the coil has no plus or minus, the direction in which the stepping motor rotates is mechanically determined.

Next to the subframe you see the hour hand gear in its original form and with its shaft shortened. Cut off 5mm, using a sharp knife. When you put the clock back together, only the shaft of the minute hand will protrude from the case, so you can securely attach a wheel.

The case with the hour hand gear back in place. Next to it you see the minute hand gear, the wheel driving the hour hand, and the two battery contacts. Only leave the minute hand. All the other gears are removed.

Drill a 3 mm (0.12”) hole in the clear plastic lid, for the wires. The hole should be near the coil. Put the clock back together. Check its mechanical operation, by temporarily attaching the seconds hand and turning it carefully. Saw off the battery compartment using a metal saw. The photo shows the final result. Only the minute hand shaft protrudes from the case.

The circuit for the Photovore by Pitronics described on the previous page is shown below:

HOW THE CIRCUIT WORKS

The circuit consists of a Solar Engine section and only activates the rest of the circuit when the electrolytic has sufficient voltage across it.

When the voltage is about 4v, the BC558 (in line with the power rail) gets turned on and the rest of the circuit is activated.

Two NAND gates form a square-wave oscillator and this signal will be passed to only one motor at a time, depending on the light received by the photo diodes or the activation of the feelers.

The two gates connected by a 10M resistor form a bi-stable switch that sits in either a HIGH or LOW state, depending on the pulse received from the feelers or photo diode. This HIGH is passed to two NAND gates that drive one of the clock motors.

If you need to drive 3-pole motors, the circuit below should be used:

Quick Links

Legal Stuff

Social Media