Table Of Contents

[Kits are available](mailto:colin@elechelp.com?Subject=Buying kit for Stepper Motor Controller&Body=Please e-mail the cost of kit for Stepper Motor Controller on prototype PC board $25.00 + postage by air mail to my country:****___**** and send details of how I can pay for it. My name is:____) for this project from Talking Electronics for $25.00 plus postage.

See more projects using PIC micros:Elektor,EPE,Silicon Chip

“Pick-A-PIC”

This project controls a UNI-POLAR stepper motor in full and half-step increments.

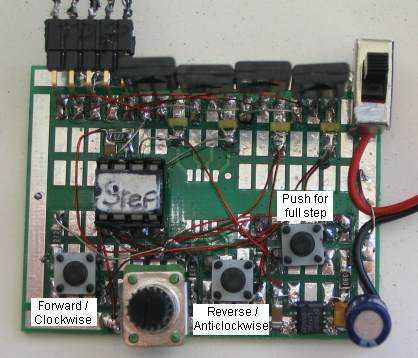

Stepper Motor Controller built on Experimenter PC board

THE STEPPER MOTOR

There are a number of stepper motors on the market and it takes a little bit of understanding to know how they work. The main difference is the number of coils and the way they are connected but there are also points to know to get the maximum torque .

A STEPPER MOTOR

A stepper motor consists of a number of stationary coils and these are turned on and pull a rotary magnet towards the coil. This action turns a shaft.

But you must turn the coils on and off at the right moment to create rotary movement.

This requires an external circuit consisting of pulses and these pulses must contain voltage and current to deliver energy to the stepper motor.

To understand how a stepper motor works, you just need to know the fact that a coil will attract a magnet when a current flows and it will repel the magnet when the current flows in the opposite direction.

In the following animation you can see an armature (rotor) being pulled around by turning on one or more coils.

Note that 8 steps can be created with 4 coils by turning them on individually or in pairs:

Here is another diagram to show how the rotor is moved by half-step intervals:

UNIPOLAR ANIMATION

The following animation shows a 6 wire stepper motor. It can be converted to a 5-wire stepper motor by connecting the two centre taps together to the positive supply. The two ends of each winding are alternately grounded to reverse the direction of the field provided by that winding.

The cross section shown is a 30 degree per step motor. Motor winding number 1 is distributed between the top and bottom stator pole, while motor winding number 2 is distributed between the left and right motor poles. The rotor is a permanent magnet with 6 poles, 3 south and 3 north, arranged around its circumference.

As shown in the figure, the current flowing from the center tap of winding 1 to terminal “a” causes the top stator pole to be a north pole while the bottom stator pole is a south pole. This attracts the rotor into the position shown. If the power to winding 1 is removed and winding 2 is energised, the rotor will turn 30 degrees, or one step.

By turning on two windings during part of the cycle, a half-step can be introduced. This is shown in the animation.

It takes three complete cycles of the control system to turn this 6-pole rotor one revolution.

HALF STEPPING

With half stepping, the drive alternates between two phases ON and a single phase ON. This increases the angular resolution, but the motor also has less torque (approx 70%) at the half step position (where only a single phase is on). This can be increased by increasing the current in the active winding. Half-stepping increases the accuracy of the output. This is what we have done in this project.

To keep the theory simple, we are not going into the waveforms needed to produce rotation, however we need to explain how the coils are connected as some motors have 5, 6 or 8 leads (wires).

4-wire stepper motors:

This type of motor has only one winding per stator pole. This is called a Unifilar winding (uni - meaning one). As we mentioned above, the winding must see reverse voltage to produce rotation and this type of motor is not covered in this project.

6-wire stepper motors:

6-wire stepper motors have two identical sets of windings on each stator pole. This is called bifilar winding and this type of winding configuration simplifies operation in that delivering current from one coil then another, wound in the opposite direction, will reverse the rotation of the motor shaft. Whereas, in a unifilar application, to change direction requires reversing the current in the same winding, as mentioned above.

5-wire stepper motors:

5-wire stepper motors simply have the centre-tap of each winding connected inside the motor or on a terminal-block.

8-wire stepper motors:

8-wire stepper motors simply have the wires from the two coils brought out separately. This arrangement offers the flexibility of either a series or parallel connection. But this will bring it to a 4-wire device and require voltage reversal to produce rotation.

You can also search the web for details on connecting the windings for high torque but this is beyond the scope of this article.

The type of stepper motor we will be covering are 5, 6 or 8-lead Unipolar stepper motors.

UNIPOLAR AND BIPOLAR STEPPER MOTORS

A Unipolar Stepper Motor has two windings per phase, one for each direction of magnetic field. You can remember the word “Uni” means only one direction of current is needed for this type of motor. This is the type we use in this project.

A Bipolar Stepper Motor has a single winding per phase. The current in a winding needs to be reversed (thus the prefix “Bi” ) in order to reverse a magnetic pole, so the driving circuit must be more complicated, typically with an H-bridge arrangement.

The following diagrams show how to connect these stepper motors:

Here are 3 UNIPOLAR Motors that can be wired and used in this project:

Convert 6-Lead 5-Lead and 8-Lead Unipolar motors by following the diagram above.

BIFILAR STEPPER MOTORS

Bifilar windings on a stepper motor are applied to the same rotor and stator geometry as a bipolar motor, but instead of winding each coil in the stator with a single wire, two wires are wound in parallel with each other. As a result, the motor has 8 wires, not four.

In practice, motors with bifilar windings are always powered as either unipolar or bipolar motors.

Note the alignment of the poles on the rotor

To use a bifilar motor as a unipolar motor, the two wires of each winding are connected in series and the point of connection is used as a center-tap.

To use a bifilar motor as a bipolar motor, the two wires of each winding are connected either in parallel or in series. With parallel connection, this allows low voltage high-current operation. With series connection, if the center tap is ignored, this allows operation at a higher voltage and lower current than would be used with the windings in parallel.

Essentially all 6-wire motors sold for bipolar use are actually wound using bifilar windings. Any unipolar motor may be used as a bipolar motor at twice the rated voltage and half the rated current on the nameplate.

IDENTIFYING STEPPER MOTOR WIRES

Most stepper motors have 6 wires, however there are some with 4, 5, or 8 wires. Each of the four coils is made up of one length of wire with two ends. One end is called live and the other end is called common. In a five-wire stepper motor all four commons are joined together, in a six-wire stepper motor two pairs of common wires are joined together, and in an eight-wire stepper motor none of the four common wires are joined together. The following diagrams show how the coils are connected:

If you do not have a schematic diagram for your stepper motor - for example if it was salvaged from an old printer - it is very easy to work out the wiring.

Use a multimeter to measure the resistance of each coil. All four coils will have identical resistance. If they did not, the motor would not function properly. The resistance may be 100 ohms. If a pair of wires measures 200 ohms, you are measuring between two live ends. In other words, you are measuring the resistance of TWO COILS.

If you have a 5 wire stepper motor, it will be very easy to find the common wire as every other wires will have a resistance of 100 ohms.

For the 6 wire stepper motor, you will have 3 wires with resistance values and another 3 wires with resistance values. The two wires with 200 ohms resistance between them, are “live,” so the other wire is “common.”

Once you have identified the “common” wire(s), you need to find the correct “phases.” This is another way of saying the correct way to connect the motor so that it rotates clockwise of anticlockwise.

You cannot simply connect the “live” wires to the project in any order.

They must be connected so that the pulses will create a rotating magnetic field.

There is no way to determine the correct way to connect a stepper motor other than viewing the output on a 4-input CRO.

So, we have to do it by trial-and-error.

Connect the stepper motor in any arrangement to the project but make sure the common goes to the positive rail, as we have already identified this wire.

Turn on the project and see if the stepper motor rotates.

If not, do not touch the first wire. Simply swap the last two wires. If this does not work, swap the 2nd and fourth wires. Then the second and third wires.

The motor will not be damaged during this process as it does not take any more current when oscillating back and forth or when rotating.

keep swapping the last three wires until the motor rotates.

PWM

To make a stepper motor rotate at the fastest RPM, we deliver a pulse of very short duration, to each of the poles and the order of delivering these pulses must be correct.

If we try to increase the RPM, we need to make the pulse shorter in duration and a point will come when the stepper motor HALTS or STOPS or FREEZES.

We now know the maximum RPM.

To decrease the RPM, we increase the length of each pulse and this produces less pulses per second. The RPM decreases.

In all of this action, the stepper motor is taking almost the same current as the voltage is being supplied almost constantly, the only difference is the pulses are longer or shorter.

But suppose you want to supply less current or supply the stepper motor with a higher voltage.

This can be done by delivering a short pulse then turning off the supply for a short period of time between pulses.

This will not alter the RPM under the following conditions: Suppose the minimum pulse-width is 5mS. Suppose the pulse-width is presently 25mS. If the pulse-width is reduced to 5mS and an off-period of 20mS, the stepper motor will retain the same RPM but consume less current.

The torque will also be reduced and this will have be checked - to see if the motor stalls under load.

This action is called “reducing-the-pulse-width” and is commonly called PULSE WIDTH MODULATION.

This is called “driving the motor with PWM.”

You can also use PWM to drive a 12v stepper motor from 24v or 36v.

By using the example above, the stepper motor is only getting a pulse of energy for 20% of the time, so that delivering a voltage such as 24v or 36v, will result in an average current that is less than driving it without PWM on 12v.

These are the main reasons for using PWM. It is not used to control the RPM. STEPPER MOTOR VOLTAGEYou can find stepper motors in all types of consumer electronics, including printers, video players, plotters and the head positioning motors from old diskette drives.

Most of these stepper motors are 12v.

However few of them are identified with the operating voltage and the simplest way to test them is to connect to 12v and read the current.

Current consumption from 50mA to 300mA is quite common and since they are generally used for very short periods of time, they will not get hot or even warm.

If you want to use them on a higher voltage, such as 24v or 36v, you will need to drive them with very short pulses and provide an off-period in the waveform so that the overall current is not above about 300mA.

This involves a pulse-width technique called PWM, mentioned above.

This can be incorporated into the project by modifying the program.

INSTRUCTIONS FOR USE

Turn the project ON and push the left button very quickly. The stepper motor will increment a half-step. Keep the button pressed and the stepper motor will rotate clockwise.

Push the right button very quickly. The stepper motor will increment a half-step. Keep the button pressed and the stepper motor will rotate anti-clockwise.

Push the top button. The project now goes to full-step mode.

Push the left button and the stepper motor rotates clockwise in full-step mode. Turn the pot to increase or decrease RPM.

Turn the project off.

Push the top button. The project now goes to full-step mode.

Push the right button and the stepper motor rotates anti-clockwise in full-step mode. Turn the pot to increase or decrease RPM.

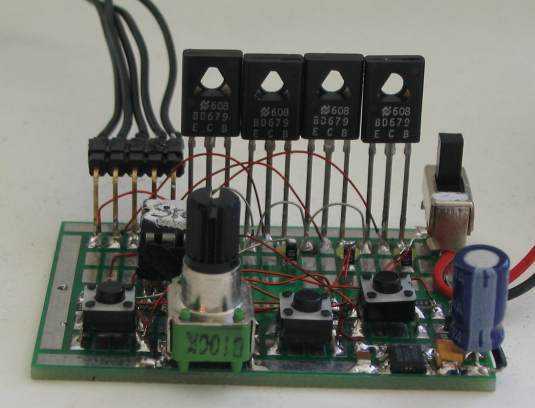

CONSTRUCTION

You can build the circuit on any type of Proto board. We have chosen our surface-mount board as it makes a neat project and you can see all the wiring at the same time.

The PROGRAM

If you want to modify the program you will need a programmer, a board to hold the 8 pin chip during programming and an adapter to connect between the programmer and PC board.

These are covered in our article “Pick-A-PIC”.

Here are the files you will need for “burning” your chip and/or modifying the program:

The following program is for viewing. It may contain spaces or hidden characters that will not compile correctly to produce a .hex file. Use the .hex file above to burn your chip or the .asm file to modify the program.

;*******************************

;**Stepper.asm** ;drives a Stepper motor forward and reverse

;13-11-2010

;*******************************

list p=12F629

radix dec

include "p12f629.inc"

errorlevel -302 ; Don't complain about BANK 1 registers

__CONFIG _MCLRE_OFF & _CP_OFF

& _WDT_OFF & _INTRC_OSC_NOCLKOUT ;Internal osc.

;_MCLRE_OFF - master clear must be off for gp3 as input pin

;******************************

; variables - names and files

;*****************************

temp1 equ 20h ;

temp2 equ 21h ;

Sw_Flag equ 25h ;switch flag for "inching"

loops equ 26h ;loops for full stepping

count equ 27h ;loops of discharge time for 100n

PotValue equ 28h ;value of pot

look equ 29h ;look for pot value every 100 loops

;***************************

;Equates

;***************************

status equ 0x03

rp1 equ 0x06

rp0 equ 0x05

GPIO equ 0x05

status equ 03h

option_reg equ 81h

; bits on GPIO

pin7 equ 0 ;GP0 100k speed pot

pin6 equ 1 ;GP1 output1 to stepper motor

pin5 equ 2 ;GP2 output2 to stepper motor

pin4 equ 3 ;GP3 Input from buttons

pin3 equ 4 ;GP4 output3 to stepper motor

pin2 equ 5 ;GP5 output4 to stepper motor

;bits

rp0 equ 5 ;bit 5 of the status register

;**********************

;Beginning of program

;**********************

org 0x00

nop

nop

nop

nop

nop

SetUp bsf status, rp0 ;Bank 1

movlw b'11001000' ;Set TRIS GP1,2,4,5 out GP3 input

movwf TRISIO

bcf status, rp0 ;bank 0

movlw 07h ;turn off Comparator ports

movwf CMCON ;must be placed in bank 0

clrf GPIO ;Clear GPIO of junk

clrf Sw_Flag

incf Sw_Flag,1 ;put a bit onto Sw_Flag

goto Main

;****************

;delays *

;****************

_uS movlw 08Ch

movwf temp1

decfsz temp1,f

goto $-1

retlw 00

;delay for pulsing servo anticlockwise

acw

movlw 60h

movwf temp1

decfsz temp1,f

goto $-1

retlw 00

_1mS nop

decfsz temp1,f

goto _1mS

retlw 00

_5mS movlw .5

movwf temp2

nop

decfsz temp1,f

goto $-2

decfsz temp2,f

goto $-4

retlw 00

_10mS movlw 0Ah

movwf temp2

nop

decfsz temp1,f

goto $-2

decfsz temp2,f

goto $-4

retlw 00

_15mS movlw .15

movwf temp2

nop

decfsz temp1,f

goto $-2

decfsz temp2,f

goto $-4

retlw 00

_18mS movlw .18

movwf temp2

nop

decfsz temp1,f

goto $-2

decfsz temp2,f

goto $-4

retlw 00

_50mS movlw .50

movwf temp2

nop

decfsz temp1,f

goto $-2

decfsz temp2,f

goto $-4

retlw 00

_100mS movlw .100

movwf temp2

nop

decfsz temp1,f

goto $-2

decfsz temp2,f

goto $-4

retlw 00

_200mS movlw .200

movwf temp2

nop

decfsz temp1,f

goto $-2

decfsz temp2,f

goto $-4

retlw 00

;delay to create value for pot for speed

PotDel movlw 040h ;40h produces 12 loops

movwf temp1

decfsz temp1,f

goto $-1

retlw 00

;***************************

; Sub Routines *

;***************************

;position of pot creates a value in PotValue

Pot bsf status,rp0

bcf trisio,0 ;Make GP0 output

bcf status,rp0

bcf gpio,0 ;make GP0 LOW

call _1mS ;create delay to discharge 100n

bsf status,rp0

bsf trisio,0 ;Make GP0 input

bcf status,rp0

clrf PotValue

call PotDel

incf PotValue,f

btfss gpio,0 ;is input HIGH?

goto $-3

retlw 00 ;returns with a value in PotValue

;******************

;* Main *

;******************

Main clrf gpio

bcf gpio,5 ;gpio,5 high for a short time

call _1mS

bsf gpio,5

nop

btfss gpio,3

goto $+2

goto $+6 ;go to half step Forward

clrf gpio

bsf gpio,1

btfss gpio,3

goto Reverse ;go to half step Reverse

goto _FS ;go to Full Step - for forward or reverse

btfsc Sw_Flag,0

goto _1HSF_

btfsc Sw_Flag,1

goto _2HSF_

btfsc Sw_Flag,2

goto _3HSF_

btfsc Sw_Flag,3

goto _4HSF_

btfsc Sw_Flag,4

goto _5HSF_

btfsc Sw_Flag,5

goto _6HSF_

btfsc Sw_Flag,6

goto _7HSF_

goto _8HSF_

_1HSF_ movlw b'00100000' ;1

goto _C

_2HSF_ movlw b'00110000' ;2

goto _C

_3HSF_ movlw b'00010000' ;3

goto _C

_4HSF_ movlw b'00010100' ;4

goto _C

_5HSF_ movlw b'00000100' ;5

goto _C

_6HSF_ movlw b'00000110' ;6

goto _C

_7HSF_ movlw b'00000010' ;7

goto _C

_8HSF_ movlw b'00100010' ;8

movwf gpio

call _200mS

clrf gpio

call _200mS

call _200mS

clrf Sw_Flag

incf Sw_Flag,1

bsf gpio,5

nop

btfsc gpio,3 ;see if sw is still pressed for full speed

goto HS_Fwd

bcf gpio,5

goto Main

_C movwf gpio

call _200mS

clrf gpio

call _200mS

call _200mS

bcf status,0 ;clear the carry

rlf Sw_Flag,1

bsf gpio,5

nop

btfsc gpio,3 ;see if sw is still pressed for full speed

goto HS_Fwd

bcf gpio,5

goto Main

;reverse - half step

Reverse

clrf gpio

bcf gpio,4 ;gpio,4 high for a short time

call _1mS

bsf gpio,4

nop

btfss gpio,3

goto Main

btfsc Sw_Flag,0

goto _1HSR_

btfsc Sw_Flag,1

goto _2HSR_

btfsc Sw_Flag,2

goto _3HSR_

btfsc Sw_Flag,3

goto _4HSR_

btfsc Sw_Flag,4

goto _5HSR_

btfsc Sw_Flag,5

goto _6HSR_

btfsc Sw_Flag,6

goto _7HSR_

goto _8HSR_

_1HSR_ movlw b'00100000' ;1

movwf gpio

call _200mS

clrf gpio

call _200mS

call _200mS

Movlw 80h

movwf Sw_Flag

bsf gpio,4

nop

btfsc gpio,3 ;see if sw is still pressed for full speed

goto HS_Rev

bcf gpio,4

goto Main

_2HSR_ movlw b'00110000' ;2

goto _D

_3HSR_ movlw b'00010000' ;3

goto _D

_4HSR_ movlw b'00010100' ;4

goto _D

_5HSR_ movlw b'00000100' ;5

goto _D

_6HSR_ movlw b'00000110' ;6

goto _D

_7HSR_ movlw b'00000010' ;7

goto _D

_8HSR_ movlw b'00100010' ;8

goto _D

_D movwf gpio

call _200mS

clrf gpio

call _200mS

call _200mS

bcf status,0 ;clear the carry

rrf Sw_Flag,1

bsf gpio,4

nop

btfsc gpio,3 ;see if sw is still pressed for full speed

goto HS_Rev

bcf gpio,4

goto Main

;half step forward

HS_Fwd

clrf gpio

bcf gpio,5 ;gpio,5 high for a short time

call _1mS

bsf gpio,5

nop

btfss gpio,3

goto Main

btfsc Sw_Flag,0

goto _1HSF

btfsc Sw_Flag,1

goto _2HSF

btfsc Sw_Flag,2

goto _3HSF

btfsc Sw_Flag,3

goto _4HSF

btfsc Sw_Flag,4

goto _5HSF

btfsc Sw_Flag,5

goto _6HSF

btfsc Sw_Flag,6

goto _7HSF

goto _8HSF

_1HSF movlw b'00100000' ;1

goto _CC

_2HSF movlw b'00110000' ;2

goto _CC

_3HSF movlw b'00010000' ;3

goto _CC

_4HSF movlw b'00010100' ;4

goto _CC

_5HSF movlw b'00000100' ;5

goto _CC

_6HSF movlw b'00000110' ;6

goto _CC

_7HSF movlw b'00000010' ;7

goto _CC

_8HSF movlw b'00100010' ;8

movwf gpio

call _5mS

clrf gpio

clrf Sw_Flag

incf Sw_Flag,1

goto HS_Fwd

_CC movwf gpio

call _5mS

clrf gpio

bcf status,0 ;clear the carry

rlf Sw_Flag,1

goto HS_Fwd

;half step reverse

HS_Rev

clrf gpio

bcf gpio,4 ;gpio,4 high for a short time

call _1mS

bsf gpio,4

nop

btfss gpio,3

goto Main

btfsc Sw_Flag,0

goto _1HSR

btfsc Sw_Flag,1

goto _2HSR

btfsc Sw_Flag,2

goto _3HSR

btfsc Sw_Flag,3

goto _4HSR

btfsc Sw_Flag,4

goto _5HSR

btfsc Sw_Flag,5

goto _6HSR

btfsc Sw_Flag,6

goto _7HSR

goto _8HSR

_1HSR movlw b'00100000' ;1

movwf gpio

call _10mS

clrf gpio

Movlw 80h

movwf Sw_Flag

goto HS_Rev

_2HSR movlw b'00110000' ;2

goto _G

_3HSR movlw b'00010000' ;3

goto _G

_4HSR movlw b'00010100' ;4

goto _G

_5HSR movlw b'00000100' ;5

goto _G

_6HSR movlw b'00000110' ;6

goto _G

_7HSR movlw b'00000010' ;7

goto _G

_8HSR movlw b'00100010' ;8

goto _G

_G movwf gpio

call _10mS

clrf gpio

bcf status,0 ;clear the carry

rrf Sw_Flag,1

goto HS_Rev

;decide on full step forward or reverse

_FS clrf gpio

bsf gpio,5

btfss gpio,3

goto $+2

goto FS_Fwd

bsf gpio,4

btfss gpio,3

goto $+2

goto FS_Rev

clrf gpio

call _1mS

goto $-10

;Full Step Forward

FS_Fwd call pot ;returns with value in PotValue

movlw .50

movwf look ;look at pot every 50 loops

movlw b'00000010' ;full step forward

movwf gpio

movf PotValue,w

movwf loops

call _1mS

decfsz loops,1

goto $-2

movlw b'00000100'

movwf gpio

movf PotValue,w

movwf loops

call _1mS

decfsz loops,1

goto $-2

movlw b'00010000'

movwf gpio

movf PotValue,w

movwf loops

call _1mS

decfsz loops,1

goto $-2

movlw b'00100000'

movwf gpio

movf PotValue,w

movwf loops

call _1mS

decfsz loops,1

goto $-2

decfsz look,1

goto FS_Fwd+3 ;don't look at pot

goto FS_Fwd ;look at pot

;Full Step Reverse

FS_Rev call pot ;returns with value in PotValue

movlw .50

movwf look ;look at pot every 50 loops

movlw b'00100000' ;full step reverse

movwf gpio

movf PotValue,w

movwf loops

call _1mS

decfsz loops,1

goto $-2

movlw b'00010000'

movwf gpio

movf PotValue,w

movwf loops

call _1mS

decfsz loops,1

goto $-2

movlw b'00000100'

movwf gpio

movf PotValue,w

movwf loops

call _1mS

decfsz loops,1

goto $-2

movlw b'00000010'

movwf gpio

movf PotValue,w

movwf loops

call _1mS

decfsz loops,1

goto $-2

decfsz look,1

goto FS_Rev+3 ;don't look at pot

goto FS_Rev ;look at pot

END

GOING FURTHER

You can add additional features to this project by writing your own program or modifying the program above.

Stepper Motor Controller - Parts List

Cost: au$25.00 plus postage [Kits are available](mailto:colin@elechelp.com?Subject=Buying kit for Stepper Motor Controller&Body=Please e-mail the cost of kit for Stepper Motor Controller on prototype PC board $25.00 + postage by air mail to my country:****___**** and send details of how I can pay for it. My name is:____)

1 - 39R SM resistor>

4 - 100R SM resistor

1 - 220R SM resistor

3 - 2k2 SM resistor

1 - 47k SM resistor

1 - 100k pot

2 - 100n SM capacitors

1 - 100u electrolytic

4 - SM yellow LEDs

1 - SM diode

4 - BD679 transistors

1 - 78L05 SM voltage regulator

1 - SPDT mini slide switch

3 - mini tactile buttons

1 - 8 pin IC socket

1 - 5 pin header

1 - 40cm fine enamelled wire

1 - 20cm fine tinned copper wire

1 - 20cm - very fine solder

1 - PIC12F629 chip (with Step routine)

1 - 4-cell battery holder

1 - battery snap

1 - Prototype PC board

Quick Links

Legal Stuff

Social Media