Table Of Contents

Page 2

When a player places his finger on the TOUCH SWITCH, the first monostable multi-vibrator consisting of gates a and b in IC1 will be triggered into its unstable state and produce a spike through the 10n capacitor to operate the second monostable. The output pin 10 is normally HIGH. It will go LOW for 1/10 second then return HIGH. It will remain in this state until your finger is removed and re-applied. The time delay of the first monostable has been carefully chosen to be longer than the second so that the circuit is fully de-bounced and can only be triggered every half-second. The second monostable has a time delay completely independent of the first and produces a short pulse which charges the 470u electrolytic via the 3k3 resistor and diode. The purpose of the diode is to prevent discharging of the electrolytic once the monostable has fallen back into its stable state and produced a LOW on pin 10.

The charging of the electrolytic is exponential and each pulse from pin 10 produces sufficient energy to raise the voltage of the 470u approximately .75v to turn on one transistor at a time in the staircase. At the bottom of the staircase, one pulse will be sufficient to illuminate one of these steps but as they increase towards the top, more than one pulse will be required.

Transistor Q1 is connected as an emitter-follower, the load being the base resistors in the staircase. The voltage across this load will be directly proportional to the voltage on the electrolytic (i.e. the base voltage) minus the .75v base-emitter voltage drop. The main purpose of the transistor is to separate the 470u electrolytic from the load of the staircase. If we were to remove this transistor the circuit would function as before except that the load of the 9 staircase transistors would tend to discharge the electrolytic rather quickly.

So, in effect, the emitter-follower transistor is providing an impedance matching arrangement to reduce the drain on the electrolytic, to a value about one-hundredth of a directly-coupled version.

The base resistors have been chosen according to the voltage they will be required to drop. Many factors influence the actual value selected for each base resistor as the impedance of the circuit changes with rising voltage and this alters the conditions considerably.

The first transistor in the staircase is Q2. It will turn on when its base voltage is .75v higher than the emitter voltage. The second transistor, instead of being connected to the ground, is connected to the base of the first transistor. It too will turn on when its base voltage is .75v higher than its emitter. This means the incoming voltage will need to be .75v + .75v or 1.5v before it will be fully turned on. This reasoning continues up the staircase so that the top transistor will require 6.75v to be turned on.

Extending back, the 470u electrolytic requires 6.75 + .75v or 7.5v and the output of the IC is .6v higher again to account for the diode drop. The IC needs an even higher output voltage to be able to supply a charging current through the 3k3 current limit resistor. To be on the safe side, the supply rail should be 7.5v + .6v + 2v = 10.1v. The need for a high supply voltage is even more important when illuminating the top LED’s 14 and 15. So much of the supply has been lost in the base-emitter junctions that 11.5v is the absolute minimum voltage if we expect to get adequate brightness from the top LED’s. This will allow us just 4v for the dropper resistor and LED’s.

You will notice the power to the 15 LED’s comes from 3 different sources. LED’s 1 to 7 and 11 are supplied directly from the 9v supply. LED 8 derives its supply from a slow cycling oscillator. This is made up of gates a and b of IC2. It forms a gated oscillator with pin 3 normally HIGH. The oscillator is triggered via pin 1. When it detects approximately half supply voltage through the high impedance resistor network comprising the 390k, 100k pot and 390k resistor, it will flash LED 8 at about 2 cycles per second.

LED’s 9 and 10 are series LED’s and need to be driven from a source slightly higher than 9v. To achieve this we must take them to the BOOST rail. LED 7, being a single LED will just operate from the 9v rail. The remaining 4 LED’s need 12v to operate. LED’s 14 and 15 are paralleled together so that they can attain full brightness from the 12v rail.

Resetting the game is accomplished by discharging the 470u electrolytic via Q13. This transistor is normally biased in the off condition with the 2M2 base-emitter resistor. When you touch the SHUT DOWN wires with your finger, a small forward bias is applied to the transistor and it turns ON to bleed the electrolytic. The light-emitting diodes will gradually turn off as the voltage on the electrolytic falls. When all the LED’s are off the quiescent current for the game is only about 100 microamps. This is so small that no on/off switch is required and even small AAA cells will last their normal shelf life.

An overlay makes construction so easy. It will take the best part of an hour to assemble the HANGMAN, even with all the parts ready at your fingertips. See the photo above if you are not sure where any of the components are placed. Use only DURACELL cells to power this game. Ordinary dry cells will not last very long as their voltage soon falls to 8v or less for a 9v battery At this voltage, the doubling circuit will be incapable of supplying sufficient voltage to light LED’s 14 and 15.

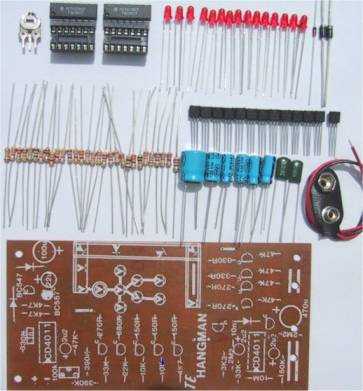

The Hangman components.

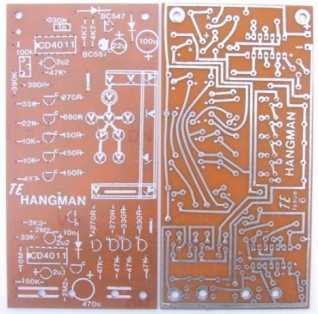

The Hangman Printed Circuit Board

PARTS LIST

- 3 - 150R resistors

- 3 - 270R

- 2 - 330R

- 1 - 680R

- 1 - 3k3

- 3 - 4k7

- 2 - 10k

- 1 - 22k

- 2 - 33k

- 5 - 47k

- 1 - 150k

- 1 - 330k

- 2 - 390k

- 2 - 2M2

- 1 - 10M

- 1 - 1n 100v green cap

- 1 - 10n 100v green cap

- 2 - 4u7 16v electrolytics

- 2 - 22u 16v

- 1 - 100u 16v

- 1 - 470u 16v

- 12 - BC547 transistors

- 1 - BC557 transistor

- 2 - CD 4011 Quad NAND

- 15 - Red 3mm LED’s.

- 1 - 100k mini trim-pot

- 1 - 1N914 or 1N4148 Diode

- 2 - 1N4002 Diodes

- 1 - battery snap

- 1 - 9v battery

- 1 - HANGMAN PC BOARD

CONSTRUCTION

Examine the printed circuit board for any holes which may be filled-in with solder. This happens during manufacture, when the copper tracks are being tinned. Clean these out with a soldering iron and needle or a length of copper wire. Whether you use a ready-made printed circuit board or a home made board, some form of printed construction is essential for a circuit of this complexity.

Follow the usual method of fitting the parts by firstly soldering the resistors in position. Refer to the layout for their positions. They can be inserted either-way-around but it’s best to fit them so that the colour bands can be easily read when you are checking them later. The boards have been silk-screened with an overlay of the parts. This will assist enormously with construction and show you their exact positions.

Next fit the jumper wires including those making up the touch wires. You can use tinned copper wire or the ends of resistors. Do not use plain copper wire as its appearance will deteriorate and become tarnished after a period of time.

The 100k mini trim pot, 3 diodes and 2 capacitors are fitted next. The diodes must be inserted with their cathode end as shown. This is identified on the component by a band. In the case of the small signal diode, it may have a blue, red or black band, depending on the type supplied. The 5 electrolytics must be inserted with the positive end as marked on the board. The positive lead is the long lead, so don’t cut them off until they have been inserted and soldered.

Next fit the 15 light-emitting diodes. These are very temperature sensitive and will be destroyed if allowed to get too hot during soldering. Hold them in position during soldering with your fingers to prevent them from getting too hot. The cathode side of the diodes all face one direction and are marked on the board with a dot. This is the short lead and if you look into the body of the LED you will see it is the largest portion inside the LED.

Lastly insert the semiconductors most vulnerable to damage. The 13 transistors are inserted as shown in the layout diagram. You will notice uniformity about the way they are inserted and this should prevent too many mistakes. Finally the two chips are fitted to the board in the IC sockets. Locate pin 1 on the chip via the dimple and align it up with pin 1 on the board as marked with a dot.

IF IT DOESN’T WORK

If your unit fails to operate for some unknown reason, it can be diagnosed with the aid of a simple piece of test equipment. This is a LED and 330R resistor connected to two jumper leads. A multimeter will also be handy but not essential. Connect the cathode of the test LED to ground and use the resistor lead as a probe. Switch on the game and test these points on 1C2 for a HIGH: Pins 3, 5, 6, 10, 11, 12, 13 and 14.

Pins 10, 11, 12, and 13 will be supplying the BOOST circuit. Notice the LED will light up very brightly when connected to the positive of the 100u electrolytic. Also touch the common emitter terminal of the transistors for a HIGH. Once you have BOOST, IC1 will be getting its voltage (boost voltage) and will be ready for test. Before checking the second IC, test each of the LED’s by taking the flying lead of the resistor to each of the resistors connected to the collectors. The test LED will light up as well as a single or pair of LED’s on the game. If only 1 LED of a pair lights up as well as the test LED, you will know that one LED has shorted during assembly due to soldering. If no LED’s light up, one of the LED’s is open circuit, and if only the test LED lights up, both LED’s are shorted. If one section of LED’s is not being turned on, the transistor could be getting incorrect biasing or suffering from a base-emitter short.

The 470u electrolytic can be charged externally via a 10k resistor connected to the positive of the battery. This will sequentially turn on the LED’s. Once the LED’s are alight, they should stay illuminated for 5 minutes or so without the voltage on the electrolytic draining away. Any gradual decline will indicate a leakage path. Remove the shut-down transistor and the staircase base resistors starting from Q10, to locate the fault. Q1 should also be checked.

The second 1/10 second TOUCH SWITCH delay output is detected on pin 4. It is normally HIGH and goes low for 1/10 second. Pin 10 is the pulse output and will flash briefly when gates c and d are pulsed via the 10n capacitor. You will be able to detect this pulse on the test LED.

If LED’s 14 and 15 do not illuminate, the battery will be slightly LOW. The circuit is fairly critical on voltage. The supply cannot deviate more than 1 volt either side of 9v.

Use this same reasoning to investigate any other of the blocks you feel, are not operating satisfactorily. Once you have run over the whole circuit, connect up the battery firmly and mount the board on a project box. The board will accept 2 small screws to finish the job. All that is left now is find an opponent and meet your challenge.

Quick Links

Legal Stuff

Social Media