Table Of Contents

PIC12F629 Data Sheet (.pdf 4,926KB)

Instruction Set for PIC12F675

See more projects using micros:

- Pic A PIC Project

- Notepad++ or VS Code

- Library of Sub-routines “Cut and Paste”

- Library of routines: A-E E-P P-Z

- AudioCRO.asm

- AudioCRO.hex

This project is a miniature Audio CRO. For those not familiar with the abbreviation “CRO,” it means “Cathode Ray Oscilloscope” and this is sometimes shortened to “SCOPE or O-Scope.”

A “CRO” is a piece of test equipment with a screen. It produces a visual indication of a waveform, via a probe, when the waveform is connected to the input terminal of the CRO.

If you connect a microphone to the probe and whistle into the mic, the CRO will produce a picture (trace) of the waveform. It will be in the shape of a sinewave. The screen is very similar to an old-style TV set (called a “picture-tube”) and the picture is created by firing a beam of electrons from the back of the tube (called the “neck’”) to the front of the tube where a layer of phosphorescent material glows when the beam hits it.

The beam of electrons is diverted from left to right via an electromagnetic field or an electrostatic field and this produces a line across the screen.

The beam is then deflected up or down by magnetic or electrostatic fields at 90° and this enables it to produce all sorts of patterns.

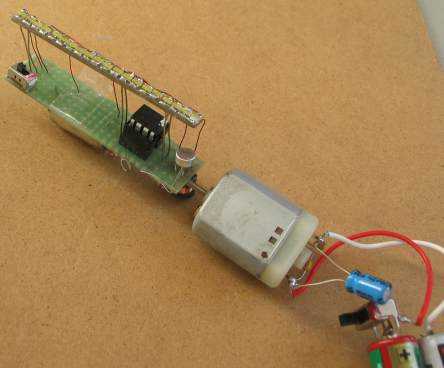

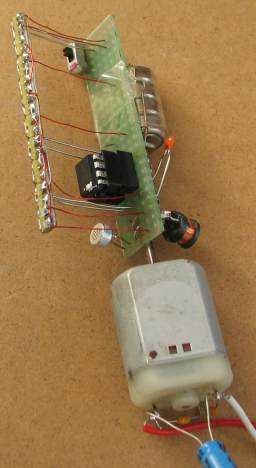

Here are some photos of the prototype Audio CRO. Note the use of surface-mount components allows a lot of parts to be placed in a very small space.

The 10mH inductor has been placed at an angle to make it less sensitive to the motor magnets so that it only picks up the field of the super-magnet placed on the end of the motor.

The motor is actually a 12v motor from the eject mechanism of a CD player. It operates down to 3v and the RPM at 3v is very low. That’s why it was chosen.

There are a lot of technical challenges to overcome when electronics is combined with mechanical devices. You will experience these when you build the project.

This is exactly what we have done in this project. But in an extremely miniaturised way.

Our screen is digital. It is rotating to produce a screen of light made up of “pixels.”We have an upright strip of LEDs and this is spun from left to right to create a screen that is 8 pixels high.

As you can see from the photos, the project is built on a small PC board containing the PIC chip, components to interface a pick-up coil and microphone to the chip and 4 cells. 16 LEDs are soldered to the edge of the board to create the “display.” The PC board is soldered to the shaft of a motor and a separate 3v supply is used to rotate the motor. We have used electro-magnetic detection to detect the starting point for each rotation of the display so that the RPM of the motor is not important. The display will remain absolutely steady, not matter how fast the shaft is rotated.

However the length of the display will contract if the motor is slowed down.

We then turn each LED on and off many times during the visual part of its rotation, making a screen resolution of up to 8 x 60. (But the audio section has a screen size 8 x 48). This might seem a small area but the project is a CONCEPT DESIGN.

CONCEPT DESIGN

It is designed to show the capabilities of one of the smallest and simplest chips in the PIC microcontroller range. It’s to “get you started” and if it were a complex project, it would be by-passed by those who we are aiming at - the BEGINNER.

Even at this basic level there are a number of features to challenge the brightest hobbyist - so be prepared for a really absorbing project.

LED MYTH

There is a generally accepted thought that the voltage across a LED is a fairly constant value. But this is not so.

As the current across it drops, the “characteristic voltage drop” also drops significantly.

For the LEDs used in this project, the voltage drops from 2.3v (when full current is flowing) to 1.66v when less than 1mA flows.

This value is important as we are placing 4 LEDs across a 5.4v supply and we need to know if any current will flow through the combination when the project is resting.

In our case, 4 LEDs at rest requires 6.64v. This means no current will flow when the supply is 5.4v (it has to be higher than 5,4v for the LEDs to start to conduct).

This is the main reason why we have had to place two LEDs in series on each output. If we had only 2 LEDs from the positive rail to 0v rail, (with the output of the chip connected to the mid-point) they would illuminate when the drive-line was in “input-mode (high-impedance mode).”

THE DISPLAY

The display is made from 16 LEDs. The LEDs are in pairs and this makes 8 “pixels.”Two LEDs are connected from an output to the positive rail and two LEDs to the negative rail.

When a control line is HIGH, two LEDs are illuminated and when it is LOW, the other two are illuminated. When the control line is an input, none are illuminated.

Both pairs of LEDs cannot be illuminated at the same time.

To make the display appear steady, the LEDs must be turned on at exactly the same instant, during each revolution. This is called REGISTRATION and is done by sensing the magnetic flux from a magnet and relying on the voltage produced by an amplifying transistor to be detected as a HIGH by GP3, the input-only line.

We have one further problem with displaying an audio waveform.

We need to SYNCHRONISE the rotation of the display with the audio. With a CRO, this is done via a feature called “triggering.”

The beam is held at the left side of the screen until the signal reaches a certain value and this makes every waveform (called a trace) retrace the previous to produce a steady picture.

Since we cannot synchronise the audio with the rotation of the display, we have used a clever feature called SAMPLE AND HOLD.

We sample the audio to produce 48 “points” and store these in registers 30h to 5Fh.

The program then waits for the start of the next revolution and displays these 48 points. It then waits for the start of the next revolution and displays the points again. It does this 30 times and takes another sample of the audio. This produces about 2 updates every second.

The result is a very steady picture.

So, there you have it. A sample-and-hold audio CRO.

USING THE AUDIO CRO

Switch the project ON, then turn the motor on.

The display will rotate and the coil will pick up the starting-location for the display.

The words “Audio CRO” will appear on the display, then shift left. When the title has moved off-screen, you can whistle into the microphone. The chip will take a sample and store 48 pieces of data.

These will be displayed on the next rotation. The image will appear on the screen for 30 revolutions then another sample will be taken.

This allows the waveform to be viewed as a fairly steady trace.

The resolution is very low but the trace will show a sinewave and by whistling at different frequencies, you will be able to get different effects on the screen.

The whole purpose of this project is to set you up for further experimentation. We have purposely used the smallest, cheapest and simplest chip in the range to get you started.

All the help to do this is on the web.

It actually consists of hundreds of pages of files and data and everything is instantly accessible, simply by connecting to the web.

You can also access a PIC Micro webring (http://www.electro-tech-online.com/) where almost any query will be answered, 24 hours a day, by technical people around the world.

POV

We mentioned above, the chip is not able to display all the pixels at the same time, since a HIGH on an output displays one of the pixel-pairs and the LOW displays the other pixel-pair.

To create letters and pictures on the display, all the LEDs need to be illuminated at some point in time. To achieve this we create the images on the display in TWO SCANS. The first pass or scan displays all the lower pixels and the second scan displays all the upper pixels. Since the rotation of the display is fairly rapid, the two images combine and all the pixels on the screen “appear” to be displayed.

This is a result of your eye holding a previous image for a short period of time and combining it with the next.

This is the way movies and television work. It is called PERSISTENCE OF VISION (POV) and allows flickering images, above 5 flickers per second, to be combined.

PIC12F629 & PIC12F675

Talking Electronics features two of the simplest 8-pin PIC chips in their projects. These chips are: PIC12F629 and PIC12F675.

They are identical except the PIC12F675 has four A-D channels and PIC12F629 has none.

This project requires an A-D channel and thus the PIC12F675 has been chosen.

The project comes with a pre-programmed chip but if you want to program the chip yourself or alter the program, Talking Electronics website has details of a programmer (PICkit-2), a programming socket (PC board) and an adapter that plugs between the programmer and Programming board.

REGISTRATION

The display is made up of 8 LEDs and these are pulsed on and off very quickly to create “pixels” and the result is an image “in the air.”

To keep the image stationary we need to turn on the LEDs at the exact same place during each revolution.

This is done with a “pick-up” coil and magnet. The flux from the magnet produces a voltage and this is amplified by a transistor and fed to the microcontroller as a HIGH.

This provides registration for the display and it works very well, producing a very steady result.

But the pick-up coil is very sensitive and will detect the magnetism from the permanent magnets of the motor.

To prevent the coil picking up the background field we have angled it to 45° and added a 100n between base and 0v. We have also reduced the gain of the transistor to 10 by adding an emitter resistor. You need to make sure the coil detects magnetism only once per revolution - preferably from the magnet placed on the body of the motor.

ATTRACT MODE

When the project is turned on, the screen shows “Audio CRO” and the letters shift left until the screen is blank.

This project is not primarily intended to show lettering as this feature is available in another of our projects. However a sub-routine has been included to show the capabilities of the display.

This leads us into…

WRITING A PROGRAM

Using a microcontroller is like being handed a blank notebook. You can write a novel, a science report or create just about anything on a piece of paper.

The same with a microcontroller, except the writing is done electronically, with lines of code called instructions that are called mnemonics, as each instruction consists of letters of a sentence, to represent the instruction. The possibilities with a micro as simple as the PIC12F675 are almost endless. That’s why we have pushed the boundaries with this micro to show what can be done.

The first thing to do is work out what requirements you need and see if they fit into the capabilities of the chip.

The chip we have used has 5 in-out lines and one INPUT-ONLY line (GP3, pin4). It also has four Analogue-to-Digital inputs, storage of data that is retained, even when the chip is turned off (called EEPROM) and timers that hold “count-values,” as well as other features.

From a beginners standpoint it is very difficult to know what a micro can do and the only way to generate this knowledge is to look at projects using a particular micro and study the program.

Rather than trying to re-invent the wheel, the simplest way to start programming is to take a pre-written project and load it into a text editor such as NotePad2 and use it as a template.

A template contains all the data for the micro and the general layout of the sub-routines. By keeping to a standard layout, you will be able to find all the sub-routines as they are placed in alphabetical order, with Tables first, then delays and Main as the last routine.

You will then be able to add your own sub-routines or “cut and paste” them from our Library of Routines.

More on this topic can be found on Talking Electronics website in articles such as ”Start Here with PIC12F629.”

At this point we just like to mention that this project is a starting point for lots of ideas and the screen is like a blank canvas for all sorts of animations and effects.

PROGRAMMING IN ASSEMBLY LANGUAGE

There are a number of ways to create the program for this project. Some require you to learn a language before programming can commence. We have decided to use the 35 instructions that come with the microcontroller.

These instructions are easy to read as each instruction consists of letters that represent a sentence.

This is called ASSEMBLY LANGUAGE and when you create a program in this way, you are programming in mnemonics. A mnemonic is a set of letters or numbers that can be read by a human and easily remembered by the programmer.

For instance, “btfss 2C,3” represents the operation: “bit test 3 in file 2C and skip the next instruction if it is set.” All the operations for our micro can be performed using about 35 instructions.

Each line of a program contains a single instruction and just before the micro is “burnt,” a software program called an assembler is used to change the instructions into bytes that can be read by the micro. The assembler will produce “hex” bytes and create a file with the extension .hex

The next piece of software you will use is called a Programmer and will take the .hex file and convert it to binary “1’s” and “0’s” for “burning” into the chip.

This process is called “programming.”

Using mnemonics is called a low-level language because the instruction can be almost directly read by the micro.

You can use higher-level languages (such as C) in which a single instruction will perform a more-complex task than one of our mnemonic instructions, but as you go further up the programming ladder you get further removed from actually understanding PIC language.

Our intent is to show what can be done with a simple 8-pin PIC chip and how a program is written.

We have made programming very simple by putting the 35 instructions in a list and sample programs are available on Talking Electronics website.

By copying and pasting a sub-routine (or even a single instruction), you cannot make a mistake. Just keep to the same layout of each instruction and place them in the correct column (the layout of a program can be seen in the sub-routine below).

There are no syntax complications, like the order of placing brackets or understanding what symbols like: ”/, ^, &&” mean and if you follow our guidelines of “copy and paste” and “add one or two instructions at a time,” you will have success.

HOW THE PROGRAM WORKS

The files for this project are:

- AudioCRO.asm

- AudioCRO.hex

The program is classified as “very simple” because it does not use any complex instructions. A complex instruction is one that is “very clever” and provides a result that is not immediately obvious.

Many of the Boolean instruction produce an answer that you have to physically create a Truth Table to see the result. Other instructions can shift a bit via the “carry” to another file and this is not immediately obvious. The only instructions that need some study are those involved with Indirect Addressing.

We have not tried to trick you with programming skills. Each instruction is clear and obvious.

But you have to remember, we are producing a fairly elaborate result, one that would amaze onlookers if it were presented as a 2 metre display on a 10 metre pole. Once the concept of registration, displaying a pixel, shifting and storing temp data is understood, the results can be expanded to any dimension.

The program starts by setting-up the A/D converter and other necessary “housekeeping.” The micro then goes to Main and executes a sub-routine called Attract.

At Attract, the micro constantly loops, waiting for the coil to pass the magnet and create a HIGH on input line GP3.

As soon as a HIGH is detected, Attract creates a display 8 pixels high x 60 pixels long, by looping a program 60 times.

The width of the display is more than 300° in circumference and it is more than can be viewed at one time. That’s why the letters are shifted to the left and eventually “drop off” the screen.

The chip is not capable of outputting all the 8 pixels at the same time so that two passes of a program are needed to fully output the data. Pixels 1, 3, 5 and 7 are displayed on Pass-1 and pixels 2,4,6 on Pass-2. The rotation of the display is fast enough to combine them to produce a complete display.

To illuminate pixels for Pass-1 the output lines must be LOW. This applies to all the LEDs we want to illuminate for the first pass and since this is common to all the 60 bytes of data, we can place these instructions in the sub-routine.

All we have to do is determine which lines are to be made LOW. This can be controlled by loading the “tris” register. This register determines if a line is INPUT or OUTPUT.

If it is input, the line will be high-impedance and have no effect on controlling a LED.

This is what we have done.

The Table contains bits for the “tris” register and it creates an INPUT or OUTPUT. When a line is made into an INPUT, it becomes HIGH-IMPEDANCE and does not have any effect on illuminating any LEDs. When it is made OUTPUT, it is LOW and turns on the required LED.

This is how we turn ON the pixels we need.

Each byte in Table1 only determines values for pixels 1, 3, 5 and 7 via GP1,2,4 and 5. The program turns on the desired LEDs and calls a short delay to produce the width of the pixel.

Next the port-lines are turned off (made high-impedance) and a short delay creates the gap between pixels.

The program loops 60 times to get 60 columns of data to produce what we call the “interlace values” for “Audio CRO.” The program then goes to the second half of the routine and produces the other 4 interlace values.

This time the bits from Table2, for the “tris” register, determine if a line is INPUT or OUTPUT and the program makes each line HIGH. This turns on the required LEDs. By the phenomenon of Persistence of Vision, the result of the two half-interlaces, produces “Audio CRO.”

It just happens that these two sub-routines are executed 60 times and then the micro returns to Main where it executes the Attract sub-routine again.

But this time a “fetch’ value is introduced to the Tables and this causes the micro to jump down the table and pick up a value and display it as the first column. This has the effect of shifting the whole display to the left and eventually, after 49 fetches, all the letters have been shifted off the display.

The speed of shifting left is determined by loading the “shift” file with “1” and this allows two half’ scans to be carried out before shifting-left.

As soon as all the wording has been shifted off the screen, the micro goes to the next section called Main1 where it waits for the coil to pass the magnet. This has been done so that the microphone is facing the user. 48 samples are taken in quick succession and placed in files 30h to 5Fh.

The program then waits for registration via the coil and outputs the 48 points on the display.

The value of each sample is obtained by a section inside the chip (called the Analogue-to-Digital Converter) that detects the voltage on GP0 and creates a value from 00 to 0FF (00 to 256) by charging a small capacitor inside the chip and determining how long it takes to charge via a resistor.

The waveform produced by the microphone and transistor amplifier is not very high and we have taken the lowest 10 units of the A/D value to represent LED1, the next 10 for LED 2 etc. This is not scientific nor is it accurate but the effect is to produce a few pixels on the screen to represent a sinewave.

The program outputs the 48 points for 30 revolutions and this produces approx 0.5sec for each image.

If you keep whistling, the screen will update approx twice per second.

That’s the program.

It only uses 400 bytes and more than 600 bytes are still available for adding new features.

The program can be improved in so many ways. For example, the two Tables can be combined into one and the program picks the bits for the first pass and then the bits for the second pass via a few transfer instructions.

Or you can add more to the message when the project is turned on.

Instead of producing a line to show the audio waveform, you could use a bar-graph, however this would require a double-pass; in the same way the letters are produced in the Attract sub-routine.

There are 8 unused files that could be used to supply 8 more points for the audio waveform.

And then there are some ideas I have not thought of.

;Audio CRO 12F675.asm

;Spinning LEDs with mic input

; 19-1-2010

list p=12F675

radix dec

include "p12f675.inc"

errorlevel -302 ; Don't complain

;about BANK 1 Registers during assembly

__CONFIG _MCLRE_OFF & _CP_OFF & _WDT_OFF

& _INTRC_OSC_NOCLKOUT

;****************************************************************

; variables - names and files

;****************************************************************

shift equ 20h ;first available file fetch equ 21h

loops equ 22h

fileA equ 23h

fileB equ 24h

fileC equ 25h

temp1 equ 26h

test equ 27h

; 30h ;first location for storing A_D value

; 5Fh ;last location for A_D value

;3 x 16 = 48 locations

;memory ends at 5Fh

status equ 03h

option_reg equ 81h

; bits on GPIO

pin7 equ 0 ;GP0

pin6 equ 1 ;GP1

pin5 equ 2 ;GP2 and T0CkI

pin4 equ 3 ;GP3 input only

pin3 equ 4 ;GP4

pin2 equ 5 ;GP5

;bits

rp0 equ 5 ;bit 5 of the status register

;****************************************************************

;Beginning of program

;****************************************************************

Start org 0x00 ;program starts at location 000

nop

nop

nop

nop ;NOPs to get past reset vector address

nop

nop

SetUp bsf status, rp0 ;Bank 1

movlw b'11111111' ;Set GPI0 input

movwf TRISIO

clrf vrcon ;Vref off (power off the comparator - saves power)

movlw b'01110001' ;111 sets internal oscillator

movwf ansel ;GPO = analogue - others digital

bcf status, rp0 ;bank 0

bsf ADCON0,0 ;turn A/D converter ON - bit 0=1

bcf ADCON0,7 ;left justified result in ADRESH (2 lowest missing)

movlw 07h ;Set up to turn off Comparator ports

movwf CMCON ;must be placed in bank 0

clrf GPIO ;Clear GPIO of junk

goto Main

;*************************************

;* Tables *

;*************************************

;Table1 for first pass for letters on display

Table1 addwf 02,1 ;Add W to the Program Counter to create a jump

retlw b'01000011'

retlw b'01000011' ;line 1

retlw b'01101101' ;

retlw b'01101101' ;"1" produces an input = LED OFF

retlw b'01101101'

retlw b'01101101' ;line 5

retlw b'01000011'

retlw b'01111111'

retlw b'01000111'

retlw b'01111111'

retlw b'01111111' ;line 10

retlw b'01111111'

retlw b'01000111'

retlw b'01111111'

retlw b'01011111'

retlw b'01100111' ;line 15

retlw b'01100111'

retlw b'01100111'

retlw b'01000001'

retlw b'01111111'

retlw b'01000111' ;line 20

retlw b'01111111'

retlw b'01011111'

retlw b'01100111'

retlw b'01100111'

retlw b'01100111' ;line 25

retlw b'01011111'

retlw b'01111111'

retlw b'01000011'

retlw b'01000001'

retlw b'01011101' ;line 30

retlw b'01011101'

retlw b'01011101'

retlw b'01011001'

retlw b'01011011'

retlw b'01111111' ;line 35

retlw b'01000011'

retlw b'01000001'

retlw b'01110101'

retlw b'01100101'

retlw b'01110101' ;line 40

retlw b'01000001'

retlw b'01100011'

retlw b'01111111'

retlw b'01000011'

retlw b'01000001' ;line 45

retlw b'01011101'

retlw b'01011101'

retlw b'01011101'

retlw b'01000001'

retlw b'01000011' ;line 50

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

;Table2 for second pass for letters on display

Table2 addwf 02,1 ;Add W to the Program Counter to create a jump

retlw b'01000001'

retlw b'01000001' ;line 1

retlw b'01111111' ;

retlw b'01111111'

retlw b'01111111'

retlw b'01111111' ;line 5

retlw b'01000001'

retlw b'01111111' ;"1" produces an input = LED OFF

retlw b'01100111'

retlw b'01011111'

retlw b'01011111' ;line 10

retlw b'01011111'

retlw b'01100111'

retlw b'01111111'

retlw b'01101111'

retlw b'01010111' ;line 15

retlw b'01010111'

retlw b'01010111'

retlw b'01100001'

retlw b'01111111'

retlw b'01000001' ;line 20

retlw b'01111111'

retlw b'01101111'

retlw b'01010111'

retlw b'01010111'

retlw b'01010111' ;line 25

retlw b'01101111'

retlw b'01111111'

retlw b'01100001'

retlw b'01000001'

retlw b'01011101' ;line 30

retlw b'01011101'

retlw b'01011101'

retlw b'00001001'

retlw b'01101001'

retlw b'01111111' ;line 35

retlw b'01000001'

retlw b'01000001'

retlw b'01110101'

retlw b'01110101'

retlw b'01100101' ;line 40

retlw b'01110001'

retlw b'01010001'

retlw b'01111111'

retlw b'01101001'

retlw b'01000001' ;line 45

retlw b'01011101'

retlw b'01011101'

retlw b'01011101'

retlw b'01000001'

retlw b'01101001' ;line 50

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

retlw b'01111111'

;************************************

;* Delays *

;************************************

;Delay 250uS

_250uS movlw 30h

movwf fileB

Del250 nop

decfsz fileB,1

goto Del250

retlw 00

;Delay 0.01 sec (10mS)

_10mS movlw 0Ah

movwf fileB

DelY nop

decfsz fileA,1

goto DelY

decfsz fileB,1

goto DelY

retlw 00

;************************************

;* Sub routines *

;************************************

;attract mode - displays Audio CRO on start-up

attract

bsf status, rp0 ;Bank 1

movlw b'11111111' ;Set GP3 input -look for inductor magnetism

movwf TRISIO

bcf status, rp0 ;bank 0

btfss gpio,3

goto $-1

;Produces first pass

movlw 00

movwf fetch ;gets value from table

movf shift,w ;offset for fetch

addwf fetch,f

movf fetch,0 ;put fetch value into w

call Table1

bsf status, rp0 ;Bank 1

movwf TRISIO ;Set tris input/output

bcf status, rp0 ;bank 0

movlw b'00000000' ;make GPIO LOW

movwf GPIO

call _250uS ;display for short time

call _00percent ;all LEDs off

call _250uS ;gap between pixels

incf fetch,f

movlw d'60'

xorwf fetch,w ;is fetch = 60?

btfss 03,2 ;test zero flag in status z=1 when same

goto $-.14

;Produces second pass

bsf status, rp0 ;Bank 1

movlw b'11111111' ;Set GP3 input -look for inductor magnetism

movwf TRISIO

bcf status, rp0 ;bank 0

btfss gpio,3

goto $-1

movlw 00

movwf fetch ;gets value from table

movf shift,w ;offset for fetch

addwf fetch,f

movf fetch,0 ;put fetch value into w

call Table2

bsf status, rp0 ;Bank 1

movwf TRISIO ;Set tris input/output

bcf status, rp0 ;bank 0

movlw b'11111111' ;make GPIO HIGH

movwf GPIO

call _250uS ;display for short time

call _00percent ;all LEDs off

call _250uS ;gap between pixels

incf fetch,f

movlw d'60'

xorwf fetch,w ;is fetch = 60?

btfss 03,2 ;test zero flag in status z=1 when same

goto $-.14

retlw 00

convert ;converts A/D value to 4 output lines

movwf test ;load the A/D value into the "test" file (2F)

movlw d'10' ;load decimal into w

subwf test,0 ;subtract d'' from test

btfss 03,0 ;test the carry flag

goto _10percent ;carry flag is SET if w is less than "test"

movwf test ;load the A/D value into the "test" file (2F)

movlw d'20' ;load decimal into w

subwf test,0 ;subtract d'' from test

btfss 03,0 ;test the carry flag

goto _20percent ;carry flag is SET if w is less than "test"

movwf test ;load the A/D value into the "test" file (2F)

movlw d'30' ;load decimal into w

subwf test,0 ;subtract d'' from test

btfss 03,0 ;test the carry flag

goto _30percent ;carry flag is SET if w is less than "test"

movwf test ;load the A/D value into the "test" file (2F)

movlw d'40' ;load decimal into w

subwf test,0 ;subtract d'' from test

btfss 03,0 ;test the carry flag

goto _40percent ;carry flag is SET if w is less than "test"

movwf test ;load the A/D value into the "test" file (2F)

movlw d'50' ;load decimal into w

subwf test,0 ;subtract d'' from test

btfss 03,0 ;test the carry flag

goto _50percent ;carry flag is SET if w is less than "test"

movwf test ;load the A/D value into the "test" file (2F)

movlw d'60' ;load decimal into w

subwf test,0 ;subtract d'' from test

btfss 03,0 ;test the carry flag

goto _60percent ;carry flag is SET if w is less than "test"

movwf test ;load the A/D value into the "test" file (2F)

movlw d'70' ;load decimal into w

subwf test,0 ;subtract d'' from test

btfss 03,0 ;test the carry flag

goto _70percent ;carry flag is SET if w is less than "test"

goto _80percent ;carry flag is SET if w is less than "test"

_00percent ;ALL LEDS OFF

bsf status, rp0 ;Bank 1

movlw b'11111111' ;Set all GP0 input

movwf TRISIO

bcf status, rp0 ;bank 0

movlw b'00000000' ;no LEDs ON

movwf GPIO

retlw 00

_10percent

bsf status, rp0 ;Bank 1

movlw b'11011111' ;Set GP0 input GP5 as output

movwf TRISIO

bcf status, rp0 ;bank 0

movlw b'00100000' ;make GP 5 high

movwf GPIO

retlw 00

_20percent

bsf status, rp0 ;Bank 1

movlw b'11011111' ;Set GP0 input GP5 as output

movwf TRISIO

bcf status, rp0 ;bank 0

movlw b'00000000' ;make GP 5 low

movwf GPIO

retlw 00

_30percent

bsf status, rp0 ;Bank 1

movlw b'11101111' ;Set GP0 2 4 5 input GP4 as output

movwf TRISIO

bcf status, rp0 ;bank 0

movlw b'00010000' ;make GP 4 high

movwf GPIO

retlw 00

_40percent

bsf status, rp0 ;Bank 1

movlw b'11101111' ;Set GP0 2 5 input GP4 as output

movwf TRISIO

bcf status, rp0 ;bank 0

movlw b'00000000' ;make GP 4 low

movwf GPIO

retlw 00

_50percent

bsf status, rp0 ;Bank 1

movlw b'11111011' ;Set GP0 2 5 input GP2 as output

movwf TRISIO

bcf status, rp0 ;bank 0

movlw b'00000100' ;make GP 2 high

movwf GPIO

retlw 00

_60percent

bsf status, rp0 ;Bank 1

movlw b'1111011' ;Set GP0 input GP2 as output

movwf TRISIO

bcf status, rp0 ;bank 0

movlw b'00000000' ;make GP 2 low

movwf GPIO

retlw 00

_70percent

bsf status, rp0 ;Bank 1

movlw b'1111101' ;Set GP0 input GP1 as output

movwf TRISIO

bcf status, rp0 ;bank 0

movlw b'00000010' ; make GP 1 high

movwf GPIO

retlw 00

_80percent

bsf status, rp0 ;Bank 1

movlw b'11111101' ;Set GP0 input GP1 as output

movwf TRISIO

bcf status, rp0 ;bank 0

movlw b'00000000' ;make GP 1 low

movwf GPIO

retlw 00

;*************************************

;* Main *

;*************************************

;Displays "Audio CRO"

;called "attract mode"

Main clrf shift ;moves display to the left by adding offset to fetch

movlw .60

movwf loops ;number of loops before display starts to shift

call attract

decfsz loops,f

goto $-2

;shifts message across screen

incf shift,f

movlw .1 ; = decimal 1

movwf loops ;number of loops before display shifts

call attract

movlw d'49' ;number of shifts before exit

xorwf shift,w ;is shift = 49?

btfsc 03,2 ;test zero flag in status z=1 when same

goto $+4

decfsz loops,f

goto $-6

goto $-.10 ;= decimal 10

;stores 48 values in files 30h to 5Fh

Main1 bsf status, rp0 ;Bank 1

movlw b'11111111' ;Set GP3 input -look for inductor magnetism

movwf TRISIO

bcf status, rp0 ;bank 0

btfss gpio,3

goto $-1

movlw 30h ;first location for storing A_D value

movwf 04h ;put value into File Select Register

bsf ADCON0,1 ;Start A/D on GP0 (pin 7)

btfsc ADCON0,1 ;has conversion finished?

goto $-1

movf ADRESH,w ;put result of conversion into w

movwf 00h ;move value into INDF (actually 30h+)

incf 04h,f ;increment FSR to 31h etc

movlw 5Fh

xorwf 04h,w ;is file 04h = 5Fh

btfss 03,2 ;test zero flag in status z=1 when same

goto $-9 ;has loops reached file 5Fh? no

;displays 48 values on screen

movlw d'30'

movwf loops ;creates the 0.5sec refresh-time for viewing display

bsf status, rp0 ;Bank 1

movlw b'11111111' ;Set GP3 input -look for inductor magnetism

movwf TRISIO

bcf status, rp0 ;bank 0

btfss gpio,3

goto $-1

movlw 30h ;first location for A_D value

movwf 04h ;put value into File Select Register

movf 00h,w ;move value from INDF (30h+) into w

call convert

call _250uS ;display for short time

call _00percent ;all LEDs off

nop ;gap between pixels

incf 04h,f ;increment FSR to 31h etc

movlw 5Fh

xorwf 04h,w ;is file 04h = 5Fh

btfss 03,2 ;test zero flag in status z=1 when same

goto $-9

decfsz loops,1 ;loops reached file 5Fh?

goto $-.19

goto Main1

;oscillator calibration

call 03ffh

movwf OSCCAL

end

MORE ON THE WEB

This project is much more complex than meets the eye. However we do not want to deter you and that’s why a pre-programmed chip is available with the kit.

There is a lot of detail available about using PIC chips, creating programs etc and these can be found on the web by simply Googling PIC12F629 and/or PIC12F675.

The web is definitely the most incredible invention since “moveable type” and since it is the result of millions of individual contributors, you will find an enormous amount of assistance at: “PIC Micro Webring.” In addition you will find information on “Talking Electronics Website.” Click: “Fish Shop Timer” in the left index.

PROGRAMMING THE CHIP

The chip can be programmed using either Talking Electronics “Multi Chip Programmer” (approx $16.00) and serial cable ($6.00) or PIC Programmer MkV (no kit for this project but its cost is less than $10.00) or MicroChip PICkit-2 programmer (approx $65.00) plus 5/6 pin connector ($3.00) and a programming socket (PCB programming board - $3.50) from Talking Electronics. Here’s the run-down.

USING MULTI CHIP PROGRAMMER or PIC Programmer MkV:

The 8-pin PIC chip is taken out of the socket on the project and fitted to the Multi Chip Programmer or PIC Programmer MkV socket and “burnt.”It is then put back into the project.

This is very easy to do.

You must have a serial port on your computer and most old-style computers (such as “desk-top” and “towers” have a 9-pin serial port at the rear of the computer) for you to do this. The software to burn the chip is IC-PROG. This is available from Talking Electronics website as well as MPASM, NotePad2 and .inc files.

This gets you started with programming for less than $30.00.

USING PICkit-2:

If you don’t have a serial port (such as for a laptop), you will need to buy the PICkit-2 programmer from Microchip (from Modtronix in Australia) and use the USB port.

Most (all) lap-top computers have a USB port and this programmer comes with 2 disks containing all the software you need.

This programmer is also very easy to use and works every time.

You will also need to assemble the 5/6 pin connector (from Talking Electronics - $3.50) that connects the programmer to the project.

The PICkit-2 is available as a kit with a pre-programmed chip for the PICkit-2 PC board from: http://www.auelectronics.com/Hardware-CB0703.htm for approx $34.99(USD) as BB0703 - Fully function PICkit 2 System Part#:BB0703. But the 2CD’s of software are not included.

The instructions for assembly can be found here:

- http://augroups.blogspot.com/2009/02/step-by-step-assembly-guide-for-cb0703.html but the cost of the kit is very nearly the same as the fully assembled kits from MicroChip:

- http://www.microchipdirect.com/productsearch.aspx?Keywords=DV164120 (cost $50.00 USD plus postage or from Modtronix in Australia). The PICkit-2 from MicroChip is a “package” that also contains 2 CD’s and an extra PC board that connects to the programmer so any 8, 14 and 20 pin micros can be programmed. The board contains 4 LEDs, a push-button and a pot as well as some extra lands so you can create a small project.

For Australian residents, PICkit-2 can be purchased from Modtronix for approx $50.00 USD plus postage and this includes 2 CD’s of software. But I am not sure if the extra board mentioned above is included in the “package.” The 5/6 pin connector that connects the programmer to our project must be purchased from Talking Electronics $3.50 - otherwise you will have to use the PC board (called an experimental board) that comes with the “package” from Microchip, to hold the chip while it gets “burnt” (programmed).

Quick Links

Legal Stuff

Social Media